The world generates over 2 billion tons of municipal solid waste (MSW) every year, and that number is expected to increase by 70% to 3.4 billion tons by 2050, according to a World Bank report.

Most of this waste still ends up in landfills or is incinerated without energy recovery, practices that emit harmful greenhouse gases, pollute local environments, and waste valuable resources.

But a transformation is underway. Waste-to-Energy (WtE) technologies are redefining how we think about garbage, shifting it from an environmental liability into a resource for powering homes, fueling industries, and creating circular value chains.

Below are some of the most innovative WtE technologies, and the organizations bringing them to life, that are helping to power the circular economy.

Anaerobic Digestion Systems

Anaerobic digestion (AD) uses bacteria to break down organic waste in oxygen-free tanks, producing biogas (mostly methane and CO₂) and digestate (a nutrient-rich fertilizer). The biogas can be burned to produce electricity and heat, or upgraded to renewable natural gas (RNG) for grid injection and vehicle fuel.

- Example:

- Nature Energy (Denmark) runs some of Europe’s largest AD plants, powering cities and supplying biogas for vehicles.

Why It Matters: Food waste accounts for nearly one-third of global MSW. AD captures its methane for energy, avoiding harmful emissions while creating renewable fuel and fertilizer.

Plasma Gasification

Plasma gasification exposes waste to temperatures as high as 10,000°F using a plasma torch, breaking it down into syngas (carbon monoxide and hydrogen) and inert slag. Unlike traditional incineration, plasma gasification produces minimal toxic byproducts.

- Example:

- Sierra Energy (US) develops modular gasification units that process unsorted waste at military bases and cities.

Why It Matters: Can handle hazardous waste, medical waste, and non-recyclables while producing a clean fuel source for power or chemical feedstocks.

Pyrolysis of Plastics

Plastics that cannot be mechanically recycled (like films and multi-layer packaging) can be broken down through pyrolysis, which heats them in an oxygen-free environment to produce pyrolysis oil, syngas, and char. The oil can be refined into diesel or used as feedstock for new plastics.

- Examples:

- Brightmark (US) operates one of the largest commercial plastic pyrolysis facilities, converting 100,000 tons annually.

- Plastic Energy (UK/Spain) produces “TACOIL” from end-of-life plastics to re-enter the supply chain.

Why It Matters: Offers a scalable solution for hard-to-recycle plastics, closing the loop in the plastics economy.

Causeartist BackOffice

Your Mission-Aligned Operations Team

From investor-ready financials to growth strategy, HR, compliance, and custom software—Causeartist BackOffice is your all-in-one operational partner. Built for impact startups, funds, and nonprofits, and powered by our experts.

Let us handle the back office—so you can stay focused on impacting the world.

Landfill Gas-to-Energy (LFGTE)

Landfills are the world’s third-largest source of methane emissions. LFGTE projects drill wells into landfill sites, capture methane from decomposing waste, and convert it into electricity or pipeline-quality gas.

- Examples:

- Waste Management Inc. (US) operates more than 130 LFGTE projects nationwide.

- Veolia (France) integrates LFG recovery into its portfolio of renewable energy systems.

Why It Matters: Captures one of the most harmful greenhouse gases and turns it into a usable energy source.

Waste-to-Hydrogen Conversion

Gasification and advanced pyrolysis can transform municipal solid waste into hydrogen fuel, a zero-emission energy carrier with huge potential for decarbonizing transportation, shipping, and heavy industry.

By extracting hydrogen from mixed waste streams, these technologies turn a disposal problem into a clean fuel solution.

- Example:

- SGH2 Energy (US) is developing a large-scale waste-to-hydrogen facility in California, expected to be one of the world’s biggest.

Why It Matters: Delivers a double win—diverting waste from landfills while producing hydrogen to power the low-carbon economy.

Algae-Based Waste Treatment

Organic waste and wastewater can feed algae growth. Algae absorb nutrients and CO₂, cleaning the water, and the harvested biomass can be processed into biofuels, feed, or bioplastics.

- Examples:

- Algenol (US) develops algae-to-biofuel technologies.

- Algoliner (Germany) builds modular algae systems for wastewater treatment and energy.

Why It Matters: Merges waste treatment with renewable fuel production, creating circular systems that mimic natural ecosystems.

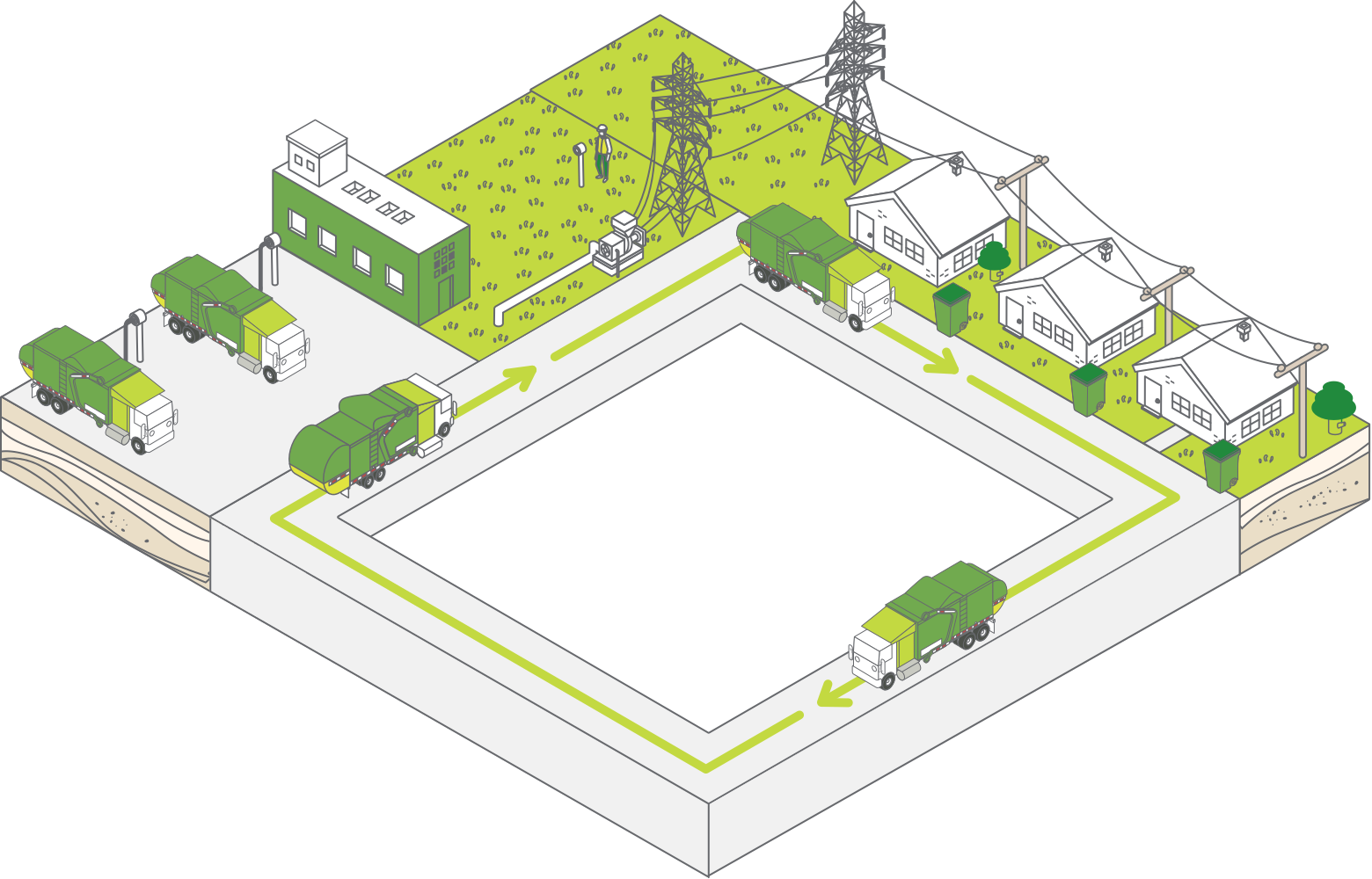

Modular Waste-to-Energy Units

Not every community has access to billion-dollar WtE infrastructure. Modular systems—often housed in shipping containers—bring local, decentralized energy recovery to small towns, island nations, and even military bases.

They can convert waste into electricity, heat, or fuels on-site, reducing both transport costs and emissions.

- Example:

- WasteFuel (US) is developing modular systems for marine fuels and airlines.

Why It Matters: Decentralizes access to WtE technology, empowering local resilience without major infrastructure.

Refuse-Derived Fuel (RDF)

Municipal waste can be sorted, dried, and processed into a high-calorific solid recovered fuel (SRF), which substitutes for coal in energy-intensive industries like cement and steel.

- Examples:

- Cemex (Mexico/Global) uses RDF to replace fossil fuels in cement kilns.

- Suez (France) operates RDF production facilities worldwide.

Why It Matters: Reduces landfill waste while helping industries decarbonize.

Ethanol from Municipal Solid Waste

Through biochemical processes, mixed household garbage can be converted into ethanol or jet fuel. Unlike crop-based biofuels, this approach doesn’t compete with food supply.

- Example:

- Enerkem (Canada) pioneered converting trash into ethanol at commercial scale.

Why It Matters: Offers a pathway to sustainable fuels while reducing reliance on landfills.

Pyrolytic Carbon Black from Tires

Scrap tires, a notorious waste stream, can be broken down into oil, steel, and carbon black through pyrolysis. Carbon black is reused in tires, plastics, and batteries.

- Examples:

- Black Bear Carbon (Netherlands) recycles tires into high-grade carbon black.

- Green Distillation Technologies (Australia) creates oil and steel from used tires.

Why It Matters: Turns one of the hardest-to-dispose waste streams into valuable raw materials.