The global move toward cleaner energy is gaining speed, yet two issues continue to shape its future. We need a dependable and sustainable supply of battery materials, and we need storage systems that can carry the grid through long periods of weak wind or sunlight.

The surge in electric vehicles and utility scale renewables has put real pressure on both fronts. It has exposed how fragile a linear, mining dependent supply chain can be and how little short duration storage can do when the grid faces extended stress.

These gaps must be solved if the energy transition is going to hold up over the long run.

A new generation of startups is rising to meet this challenge, fundamentally disrupting both the Circular Economy for battery materials and the Long-Duration Energy Storage (LDES) market.

These innovators are not just fixing problems; they are building the technological and logistical backbone of a truly resilient, decarbonized grid.

The Challenge: Supply Chain Security and Grid Intermittency

Today's lithium-ion batteries—the workhorse of the energy transition, rely on increasingly scarce and geopolitically sensitive critical minerals like lithium, cobalt, and nickel.

Mining these virgin materials carries a significant environmental footprint.

Simultaneously, renewables like wind and solar require storage solutions capable of bridging multi-day, seasonal, or even weather-related gaps in energy production—a capacity far exceeding the standard two-to-four-hour duration of typical lithium-ion systems.

The following startups, a strategic mix of recycling pioneers and LDES developers, are deploying highly technical solutions to address these twin pressures and redefine the future of the electricity grid.

The Startups Driving Innovation

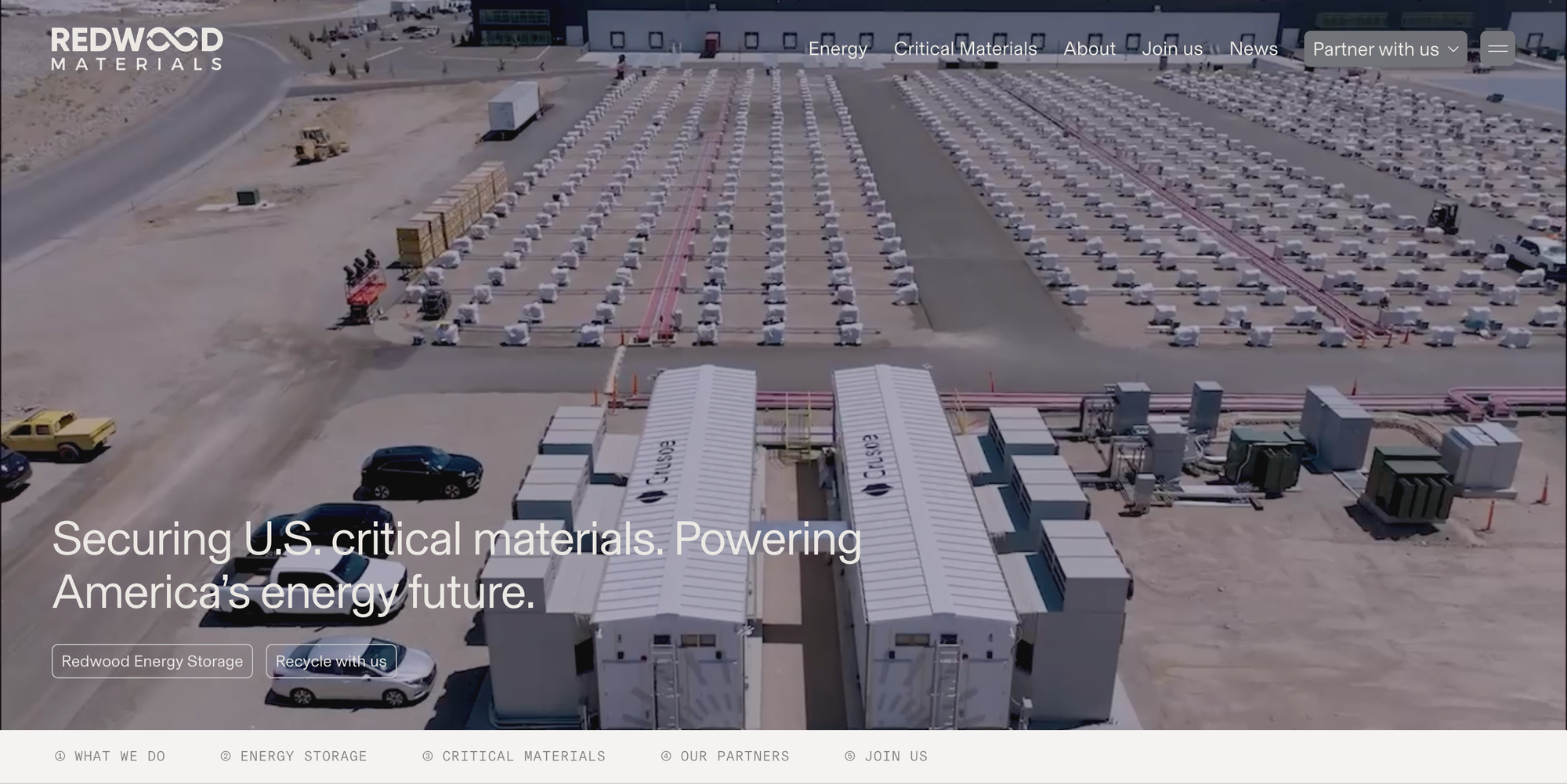

Redwood Materials 🇺🇸

- Core Innovation: Vertically integrated, full-service domestic battery supply chain. Redwood accepts end-of-life batteries, recovers 98% of nickel, cobalt, and copper, and over 80% of lithium. Crucially, it then refines these materials and re-manufactures them directly into anode and cathode components for new US battery production.

- Impact on the Grid/Supply Chain: It is creating North America’s first true closed-loop battery supply chain, significantly reducing reliance on Asian processing and securing a domestic source of critical materials.

- Key Data Point: Secured a $2 billion loan from the U.S. Department of Energy (DOE) to expand its manufacturing capacity.

Ascend Elements 🇺🇸

- Core Innovation: Proprietary Hydro-to-Cathode direct precursor synthesis process. Instead of simply extracting metals, Ascend's method produces battery-grade cathode precursor and cathode active materials directly from "black mass" (shredded batteries).

- Impact on the Grid/Supply Chain: Their process is designed to be chemistry-agnostic and drastically reduces energy intensity and cost compared to traditional hydrometallurgy by eliminating several intermediate steps.

- Key Data Point: Claims its recycled cathode materials result in up to 90% fewer carbon emissions than those made from virgin metals.

Cylib 🇩🇪

- Core Innovation: A highly efficient, water-based recycling process (specialized hydrometallurgy) developed at RWTH Aachen University. It achieves high recovery rates for traditionally difficult materials like graphite and lithium.

- Impact on the Grid/Supply Chain: Offers a recycling solution that is scalable and less energy-intensive, allowing high-purity recovery of all key components, including an industry-leading high-purity recovery of lithium.

- Key Data Point: Achieved a total funding of over $100 million in its first few years, demonstrating significant investor confidence in its technology.

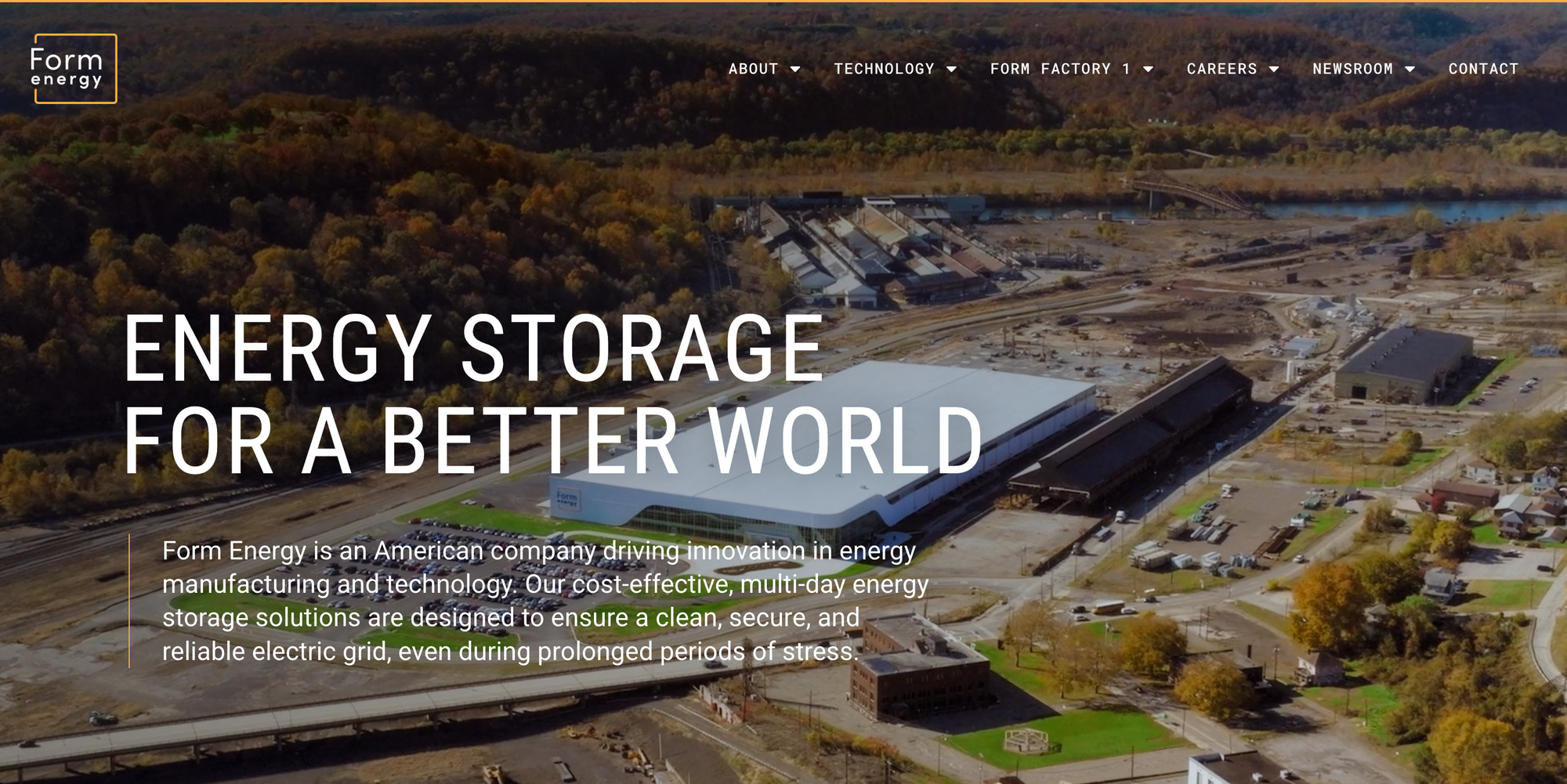

Form Energy 🇺🇸

- Core Innovation: The Iron-Air Battery system. This technology utilizes the reversible rusting process—a cheap, safe, and globally abundant material—to store energy.

- Impact on the Grid/Supply Chain: Designed to store electricity for 100+ hours (multi-day duration) at a fraction of the cost of lithium-ion, allowing utilities to replace gas-fired peaker plants and ensure grid reliability during prolonged periods of low sun or wind.

- Key Data Point: Targeting a cost point of less than $20/kWh, making multi-day storage economically feasible for the first time.

ESS Tech 🇺🇸

- Core Innovation: Iron Flow Batteries (or all-iron flow batteries). These utilize abundant iron and salt in a non-flammable, water-based electrolyte to achieve storage durations of 4 to 12 hours.

- Impact on the Grid/Supply Chain: Their systems provide long life (25,000 cycles) and deep discharge capability with no degradation over time, offering a resilient, non-toxic, and safe alternative to lithium-ion for utility and commercial applications.

- Key Data Point: Their technology is manufactured in the U.S. and is inherently non-flammable, mitigating significant safety risks associated with large-scale storage.

Antora Energy 🇺🇸

- Core Innovation: Thermophotovoltaic (TPV) technology paired with massive, inexpensive blocks of carbon. It converts surplus renewable electricity into heat, storing it in the carbon blocks at extremely high temperatures, and then converting that heat back into electricity or delivering it directly to industrial customers as high-temperature process heat.

- Impact on the Grid/Supply Chain: Solves the decarbonization challenge for industrial heat (a massive source of global emissions) while simultaneously acting as a multi-day grid storage solution.

- Key Data Point: Aims to provide industrial heat and power at costs competitive with natural gas, accelerating decarbonization in the heavy industry sector.

Moment Energy 🇨🇦

- Core Innovation: Second-Life Battery Energy Storage Systems (BESS). Moment takes retired EV batteries that no longer meet automotive performance requirements but still have 70-80% of their capacity, and repurposes them for stationary grid and commercial storage.

- Impact on the Grid/Supply Chain: Dramatically extends the useful life of a battery, maximizing the value of the embedded materials before they enter the recycling stream, significantly enhancing the circular economy model.

- Key Data Point: Provides modular BESS solutions for remote microgrids and commercial power users at a lower capital cost than systems built with new cells.

Eos Energy Enterprises 🇺🇸

- Core Innovation: Zinc-Powered Battery Storage. Eos develops Znyth® aqueous zinc battery modules, offering a 3- to 12-hour storage solution that uses widely available and low-cost materials: zinc, salt, and water.

- Impact on the Grid/Supply Chain: Provides a domestically manufactured, non-lithium, non-flammable, and highly durable alternative to support peak shaving, load shifting, and firming intermittent renewables.

- Key Data Point: Their Z3 Cubes are modular and scalable, designed to withstand extreme temperatures and offer minimal degradation over 10,000 cycles.

EnergyX 🇺🇸

- Core Innovation: Advanced lithium extraction and processing technologies, specifically Lithium Ion Transport and Separation (LiTAS™) membrane technology.

- Impact on the Grid/Supply Chain: While not a recycler, EnergyX dramatically improves lithium production efficiency from brine sources. This leads to a more affordable and consistent lithium supply, which in turn helps speed up the deployment of energy storage projects and lowers capital costs for BESS.

- Key Data Point: Claims its direct lithium extraction (DLE) technology can recover significantly higher yields of lithium compared to traditional evaporation ponds.

Ecobat 🇺🇸/🇬🇧

- Core Innovation: Global battery recycling giant with a growing lithium-ion division complementing its historical lead-acid battery expertise.

- Impact on the Grid/Supply Chain: Ecobat’s immense scale and established global footprint give the recycled materials market stability in a period of rapid battery adoption. This provides a steady, reliable source of recycled materials that utility storage developers rely on.

- Key Data Point: Operates facilities across Europe, North America, and South Africa, making it one of the largest recyclers of battery materials globally.

Key Technology Trends Analysis

The success of these startups underscores a major technological shift in the clean energy sector:

- The Rise of Non-Li-ion LDES: The investment in Iron-Air, Zinc-Air, and Flow Batteries confirms the market's need to complement lithium-ion's short-duration strength with long-duration affordability and safety, especially for utility-scale applications.

- The Circular Economy Imperative: Recycling is transitioning from simple metal recovery to sophisticated Hydro-to-Cathode and Direct Recycling processes. This means recovering not just the raw metals (critical minerals) but the complex compounds that can immediately be reformed into new battery components, drastically cutting cost and emissions.

- Maximum Material Utilization: The emergence of Second-Life BESS demonstrates a commitment to maximizing the economic and energy value of every battery module, making the transition to a Virtual Power Plant (VPP) architecture more efficient.